Step1

Preforming

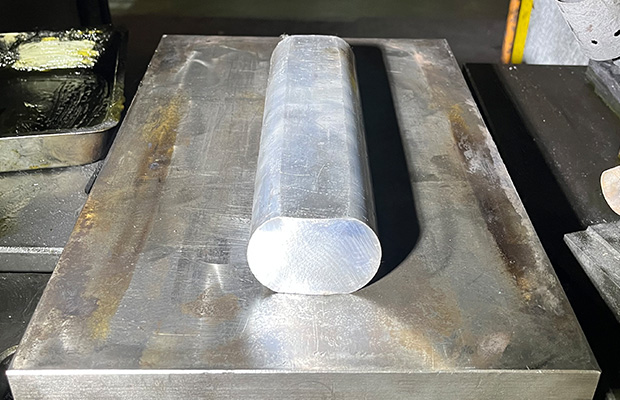

Roller Forging Preforming

Suitable for aluminum alloy rod and shaft products. Effectively use raw materials, reduce forging pressure, and extend mold service life.

Suitable for aluminum alloy rod and shaft products. Effectively use raw materials, reduce forging pressure, and extend mold service life.

Other Preforming(Flattening)

Suitable for other aluminum alloy products. Effectively use raw materials, reduce forging pressure, and extend mold service life.

Suitable for other aluminum alloy products. Effectively use raw materials, reduce forging pressure, and extend mold service life.

Step2

Pre-forging

Fill the raw material into the pre-forging die cavity to deform the forging parts close to the final shape and dimension.

Step3

Trimming & punching

Trim the horizontal flash or punching recess to make the appearance and shape of the forging parts meet the drawing requirements.

Step4

Complete Forging

The pre-forged forging parts is finally deformed to the final shape and dimension.

Step5

Heat Treatment

T4 Solid Solution Heat Treatment

A preparation process before aging strengthening. The aluminum alloy is heated to a predetermined solid solution temperature, held for a suitable time, and then rapidly quenched and cooled to form a supersaturated solid solution in the aluminum metal matrix.

A preparation process before aging strengthening. The aluminum alloy is heated to a predetermined solid solution temperature, held for a suitable time, and then rapidly quenched and cooled to form a supersaturated solid solution in the aluminum metal matrix.

T6 Aging Heat Treatment

After T4 solid solution heat treatment, artificial aging heat treatment at a specific temperature is performed to strengthen the alloy products to obtain the required physical-mechanical properties.

After T4 solid solution heat treatment, artificial aging heat treatment at a specific temperature is performed to strengthen the alloy products to obtain the required physical-mechanical properties.

Step6

Vibration & Grinding

In terms of the principle of mutual friction through vibration, smooth the surface of the workpiece and remove the original rough and uneven surface.

Step7

Whitewashing

Clean the aluminum material with surfactant cleaning technology and a white surface can be obtained, which can be painted, bonded, and colored after drying.

Step8

Sandblasting

A destructive processing method for the surface of the material. Use fine abrasive sand particles to impact the surface of the material, causing the surface to produce granular depressions to form a matte or eroded surface. Improve the smoothness of material surface.