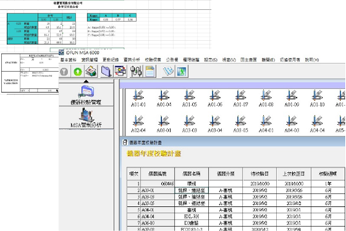

ERP

Enterprise Resource Planning(ERP) is an operation management software that integrates enterprise processes, It uses a modular approach to manage the main financial accounting, supply chain, operations, reporting, manufacturing, sales and human resources in the enterprise's internal value chain. ICS continues to improve the production management and gradually introduces fully automated production, based on smart machinery, combined with sensing instruments, robotic arms, automatic detection, ERP system, lean management and other technologies in order to build a complete " Smart Manufacturing System".

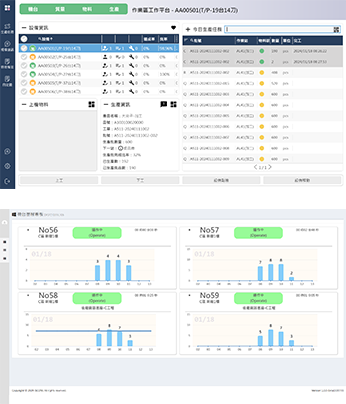

MES

Manufacturing Execution System(MES) is a system that integrates manufacturing processes from work sheet, production, equipment management, maintenance, quality control to warehousing, incoming and outgoing merchandise, etc. It is the foundation of smart manufacturing applications. Assist factories in manufacturing data & process automation, reducing the need for manual input, implementing standardized process management, production history, quality management, material management and traceability, real-time semi-finished goods management, etc. Improve manufacturing accuracy and accelerate the management decision-making process.

Through barcode connection with tablets, electronic kanban and other equipment, the intelligent logistics system provides digital, real-time, automated and other intelligent response and monitoring operations, thereby improving on-site production efficiency, order delivery commitments and inventory turnover.

Through barcode connection with tablets, electronic kanban and other equipment, the intelligent logistics system provides digital, real-time, automated and other intelligent response and monitoring operations, thereby improving on-site production efficiency, order delivery commitments and inventory turnover.

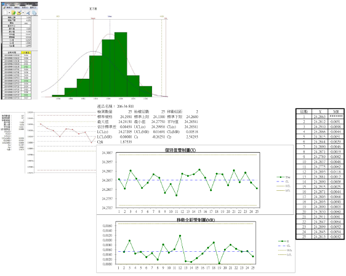

SPC

Statistic Process Control System(SPC) can output many statistic diagrams like Xbar-R, Xbar-S, X-Rm, P/Pn chart, C/U chart, Pareto chart, CPK terms, scatter diagram, and defect transition diagram by the collected database. With the clear record of each defect cause and analysis, we can understand the product quality comprehensively.

MSA

Measurement System Analysis System(MSA) can monitor the deviation, repeatability, reproducibility, stability, and linearity.

Evaluate the variation and precision of each inspection tools to prevent human or tool bias, increase inspection reliability.

By recording all of the necessary information of each instrument, including the specification, calibration cycle time, calibration history, and calibration process, the system can ensure all of the inspection instrument is under well controlled.

Evaluate the variation and precision of each inspection tools to prevent human or tool bias, increase inspection reliability.

By recording all of the necessary information of each instrument, including the specification, calibration cycle time, calibration history, and calibration process, the system can ensure all of the inspection instrument is under well controlled.