Confirm the dimension of the workpiece and use gauges to check each screw thread.

Fully inspect the appearance of the workpiece before hanging up on plating rack.

Oil removal and cleaning.

Make the part surface bright and smooth.

Remove stains and ashes on the surface after chemical polishing to obtain a relatively clean surface.

- General anodizing: Place the workpiece in a low-temperature electrolyte and applying electric current to form an oxide film on the surface.

- Hard anodizing: Place the workpiece in an extremely low temperature electrolyte and applying electric current to form an extremely hard oxide film on the surface.

Inspect the film thickness of the workpiece.

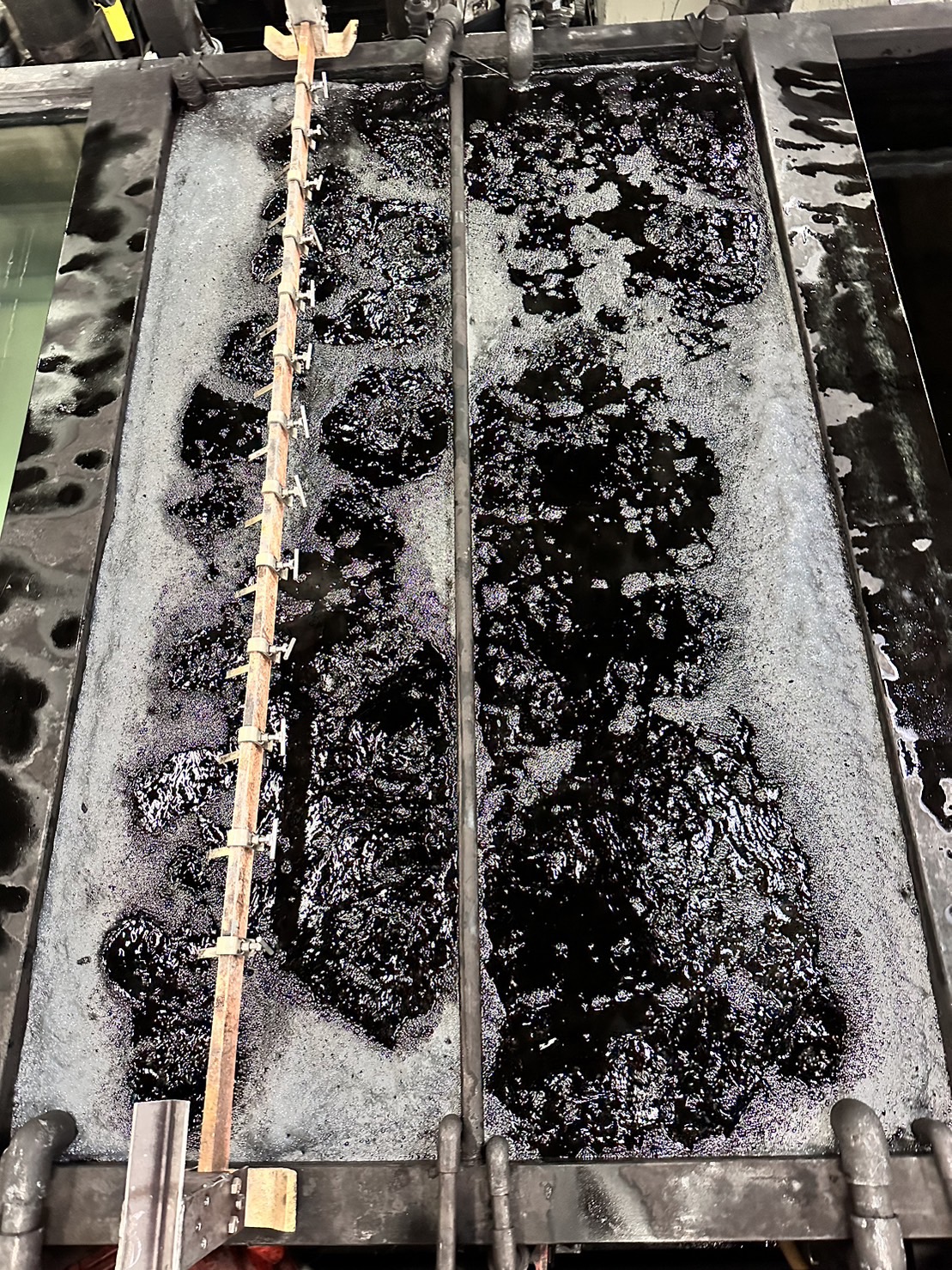

Soak the workpiece into the black dyeing tank to make the appearance black.

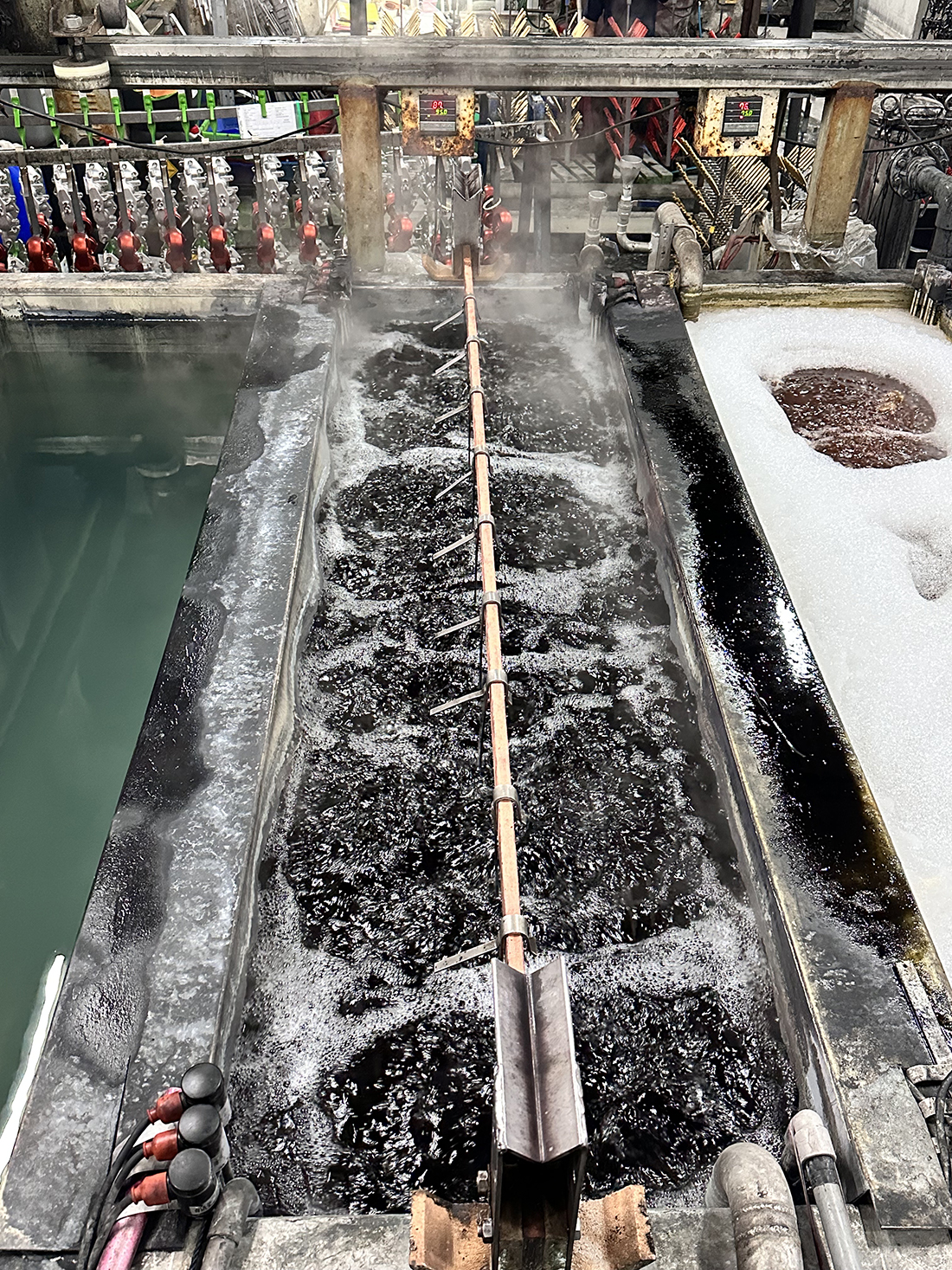

It is a post-treatment process of anodizing. Seal the pores of the oxide layer to become a non-adsorbent surface, or infiltrate some substances into the pores of the oxide layer to change or improve the properties of the oxide layer. The sealed oxide film is no longer adsorbent and is wear-resistant and temperature-resistant. Insulation properties are also enhanced.

Use an air gun to blow the workpiece to make it dry.

Fully inspect the appearance of the workpiece after removing from the plating rack.

Use extremely high-intensity laser light to continuously illuminate the object, allowing the object to partially reach the melting point, softening and can be cut downward. Combine with high-pressure airflow to melt or vaporize the object and the generated waste gas is blown away. Achieve a more precise cutting effect than the die cutting.

Complete the finished product inspection before shipment.